Destructive Test Equipment

Train & qualify welders quickly and accurately with destructive weld testing equipment from Triangle Engineering. Heavy, rugged construction provides for a long service life of reliable weld testing.

7 products

Showing 1 - 7 of 7 products

Showing 1 - 7 of 7 products

Display

View

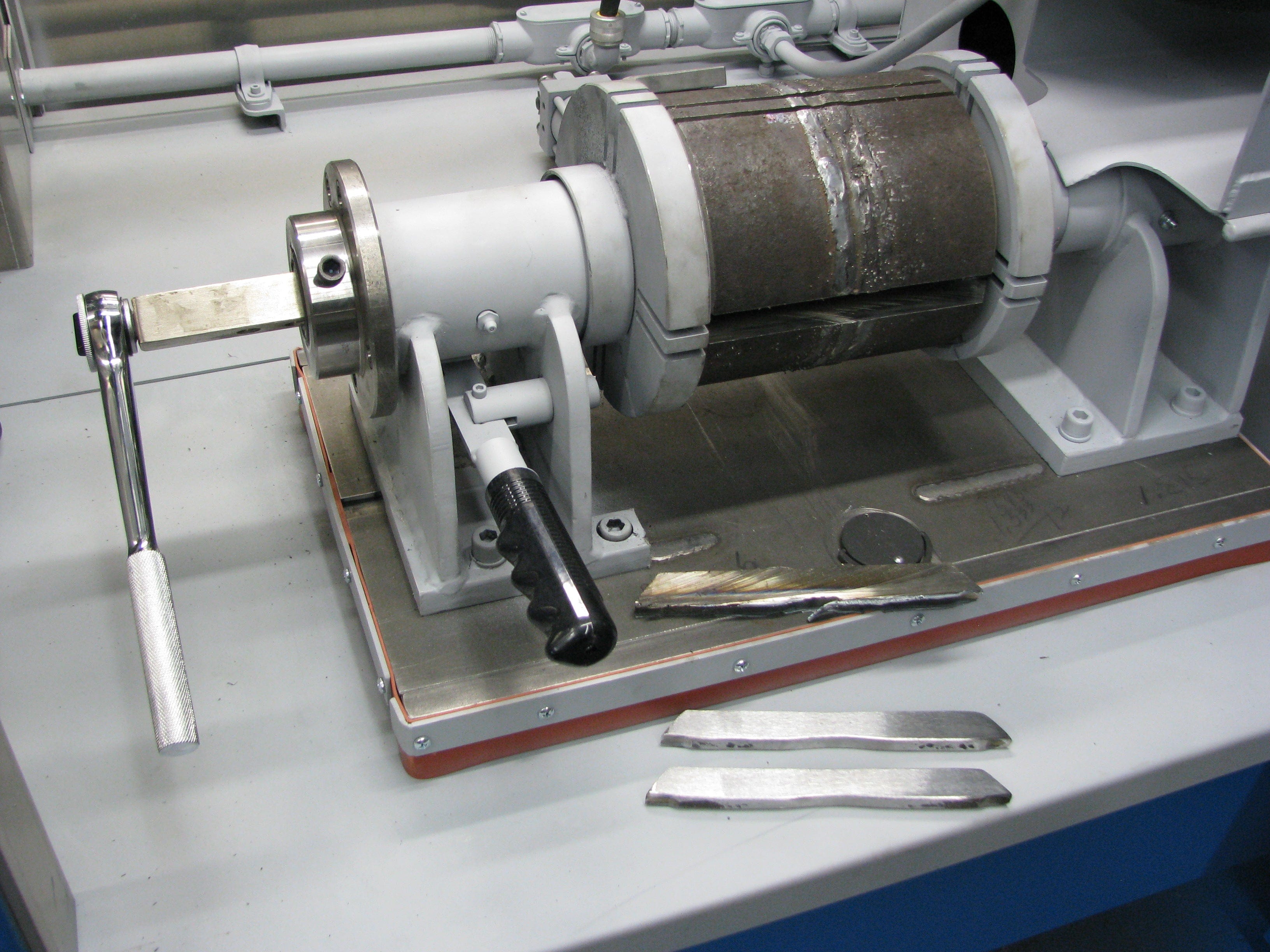

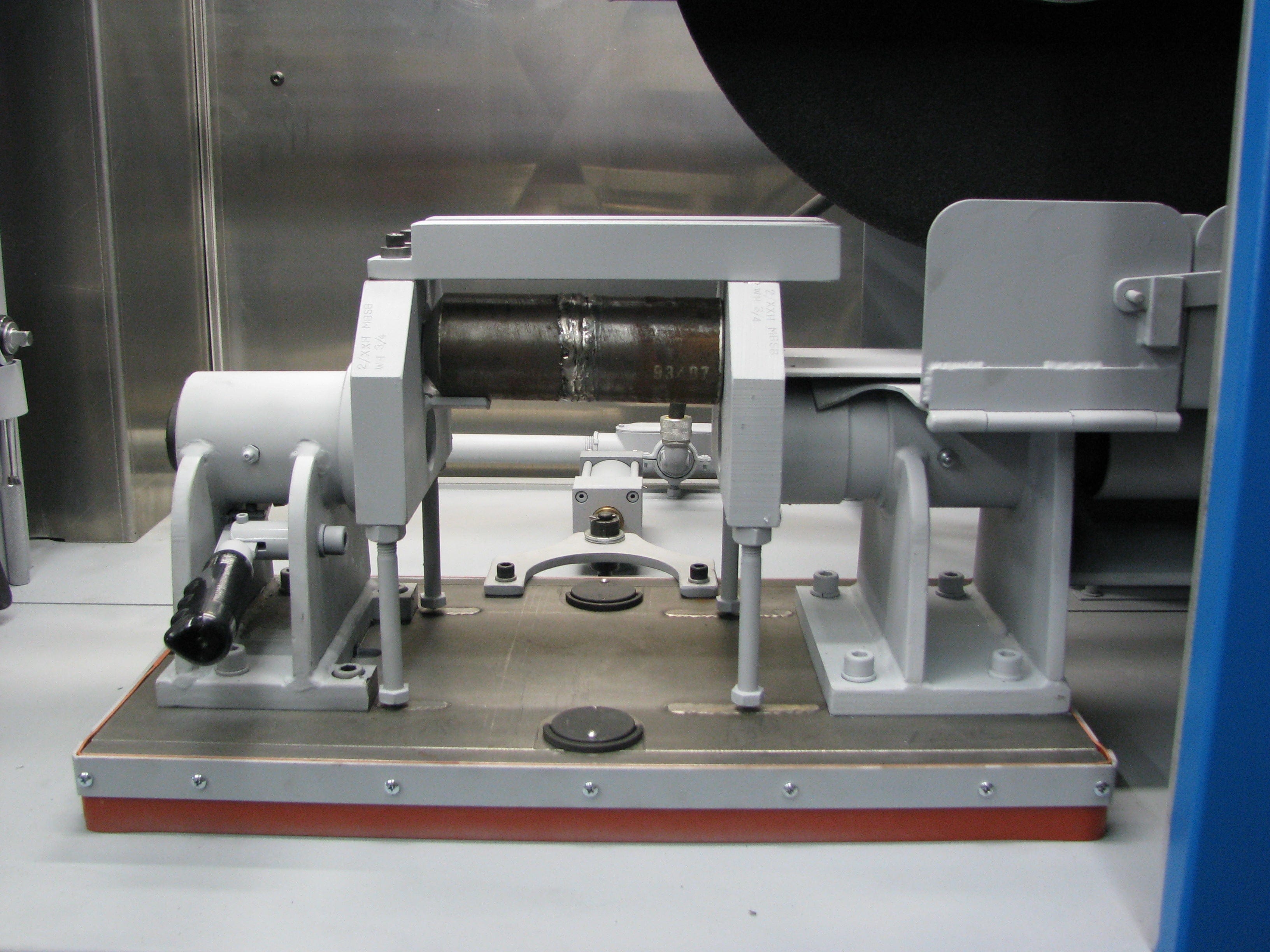

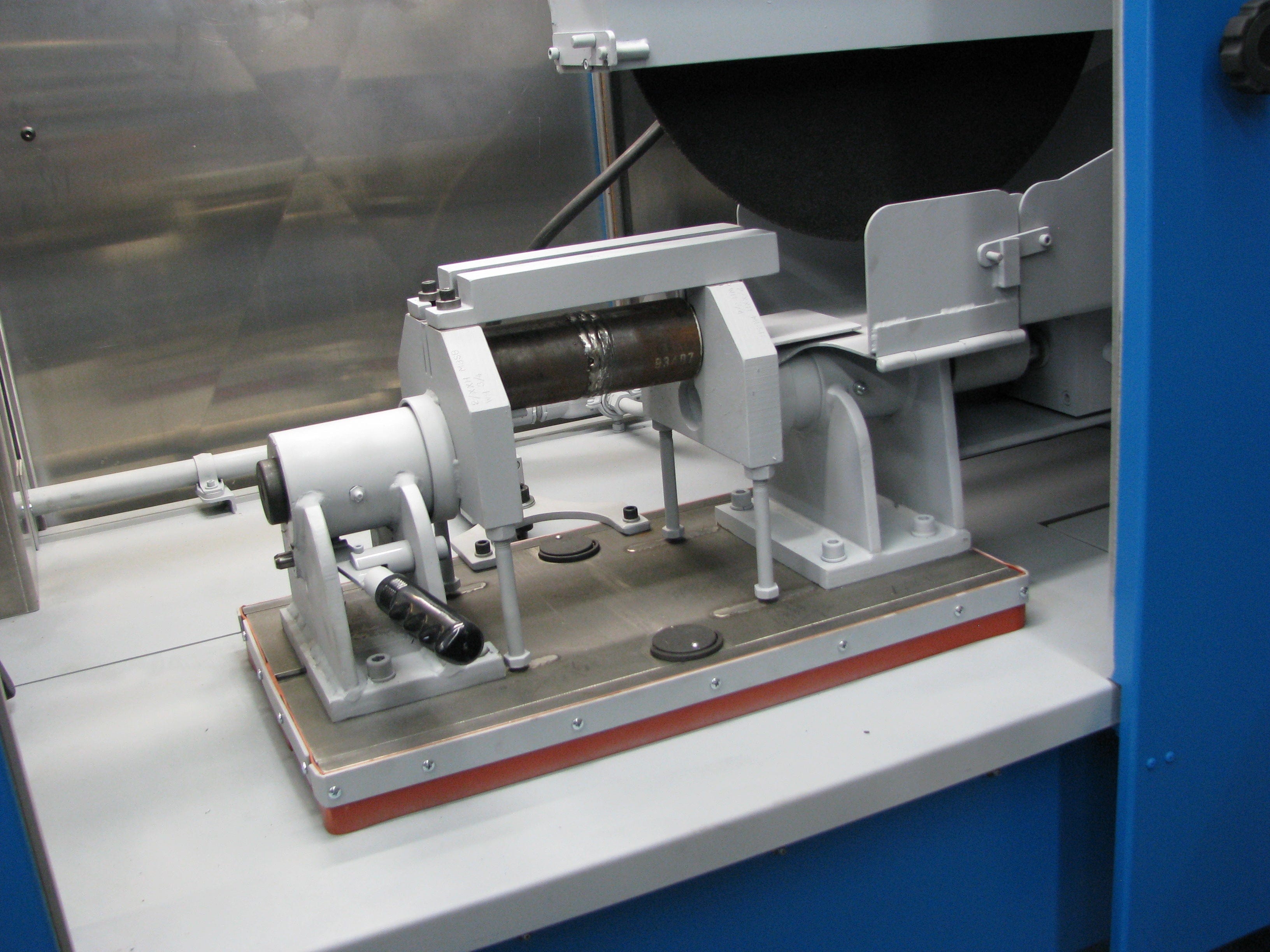

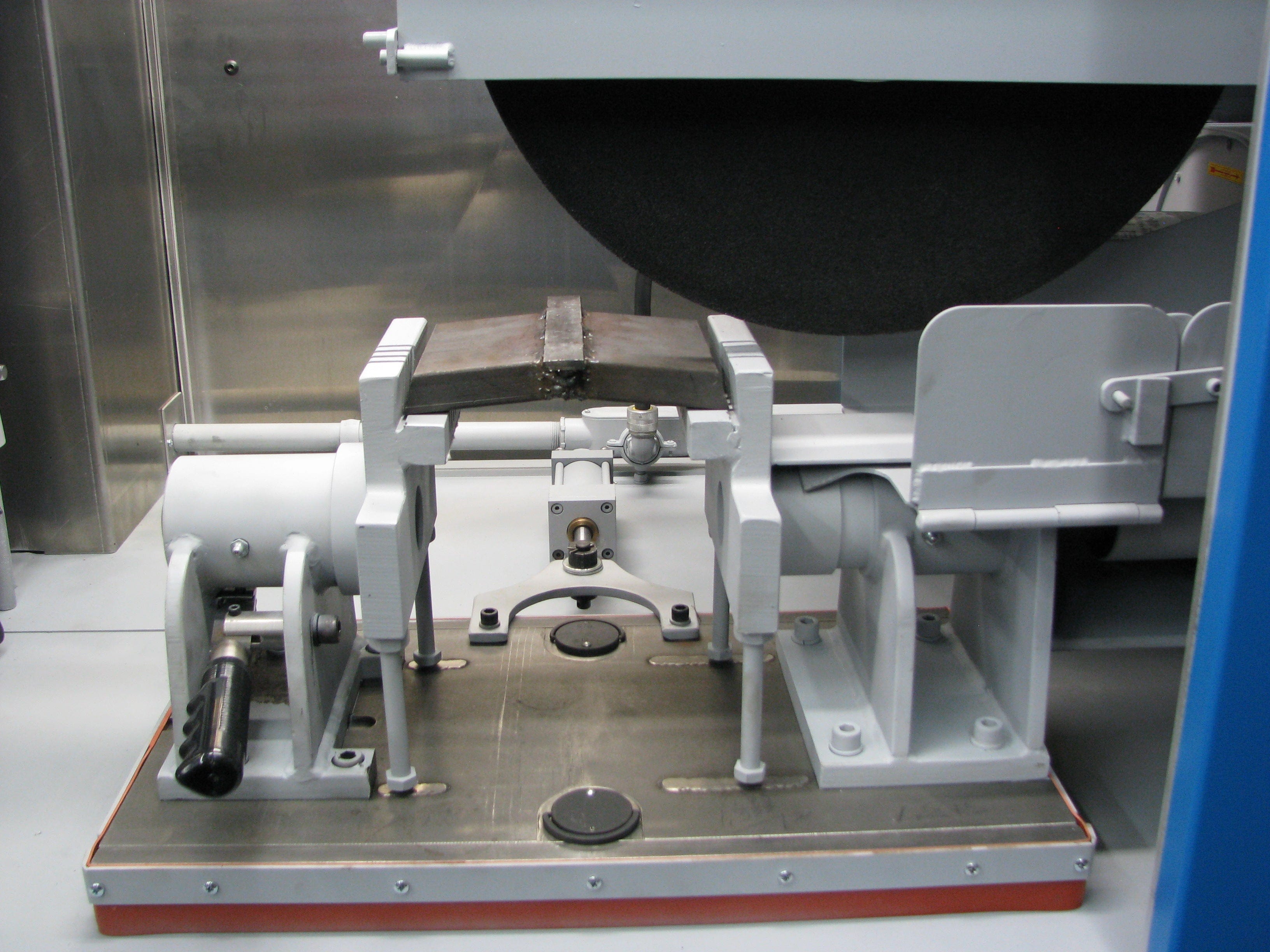

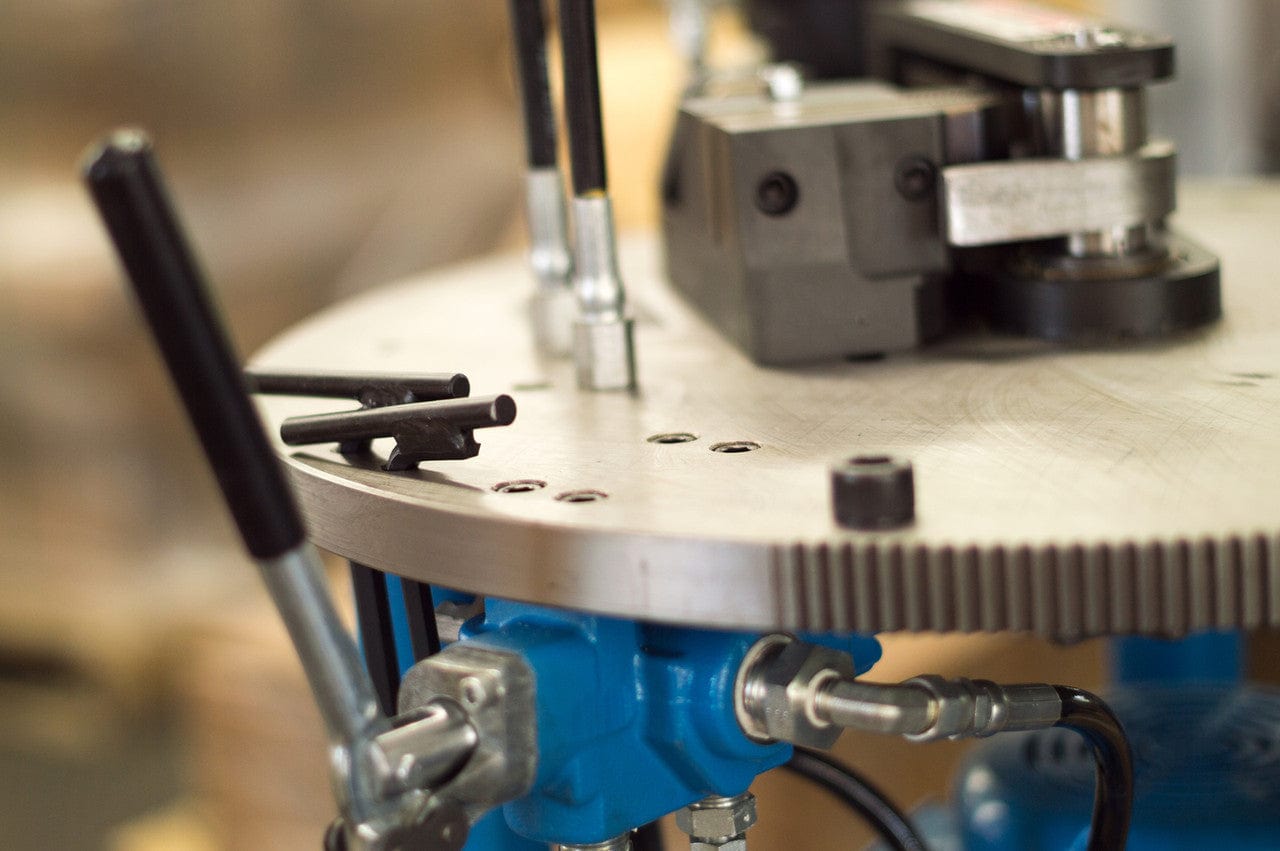

Hydraulic Wrap Around Bender, WTB-HRA

Sale price$11,880.00

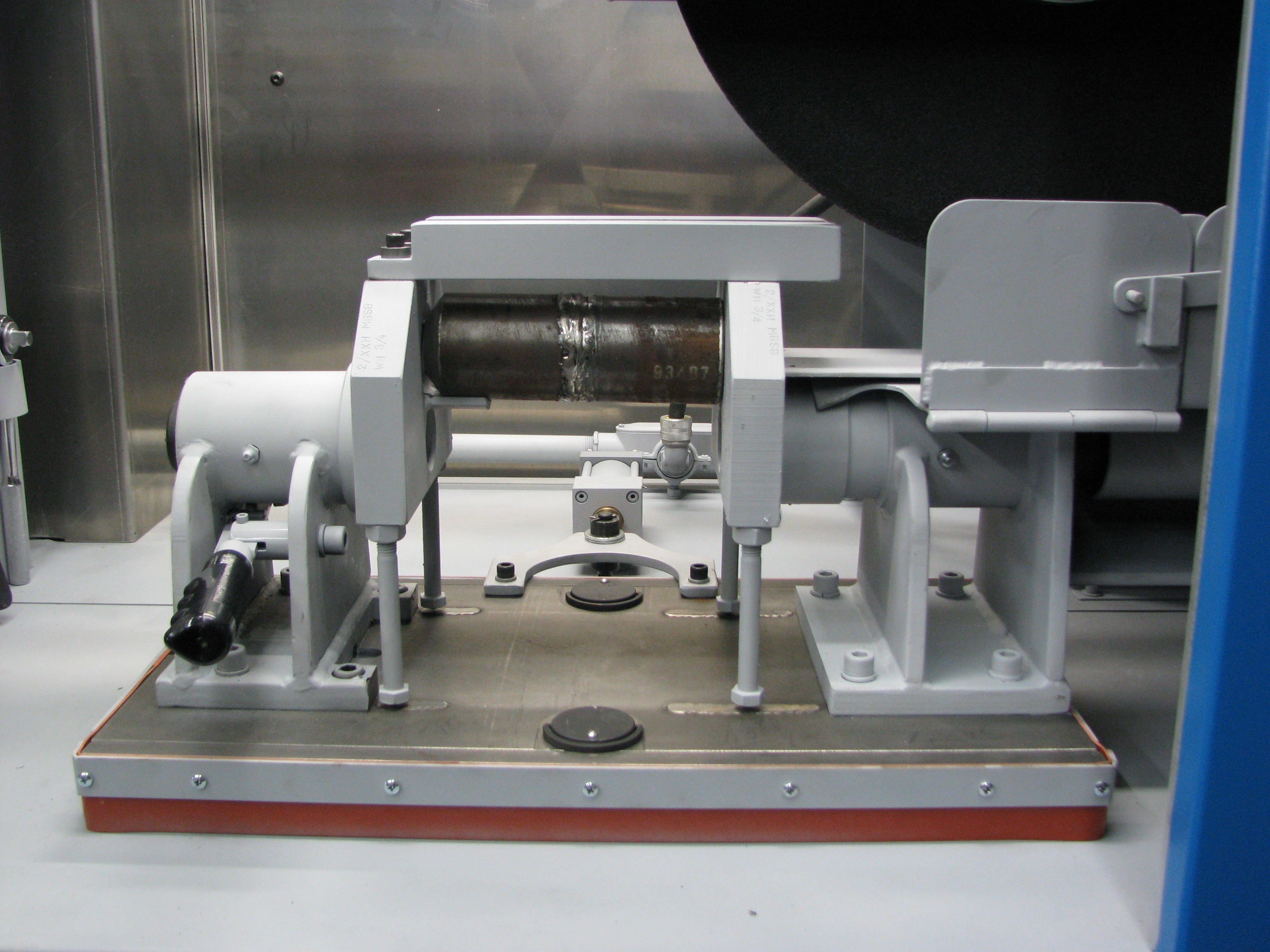

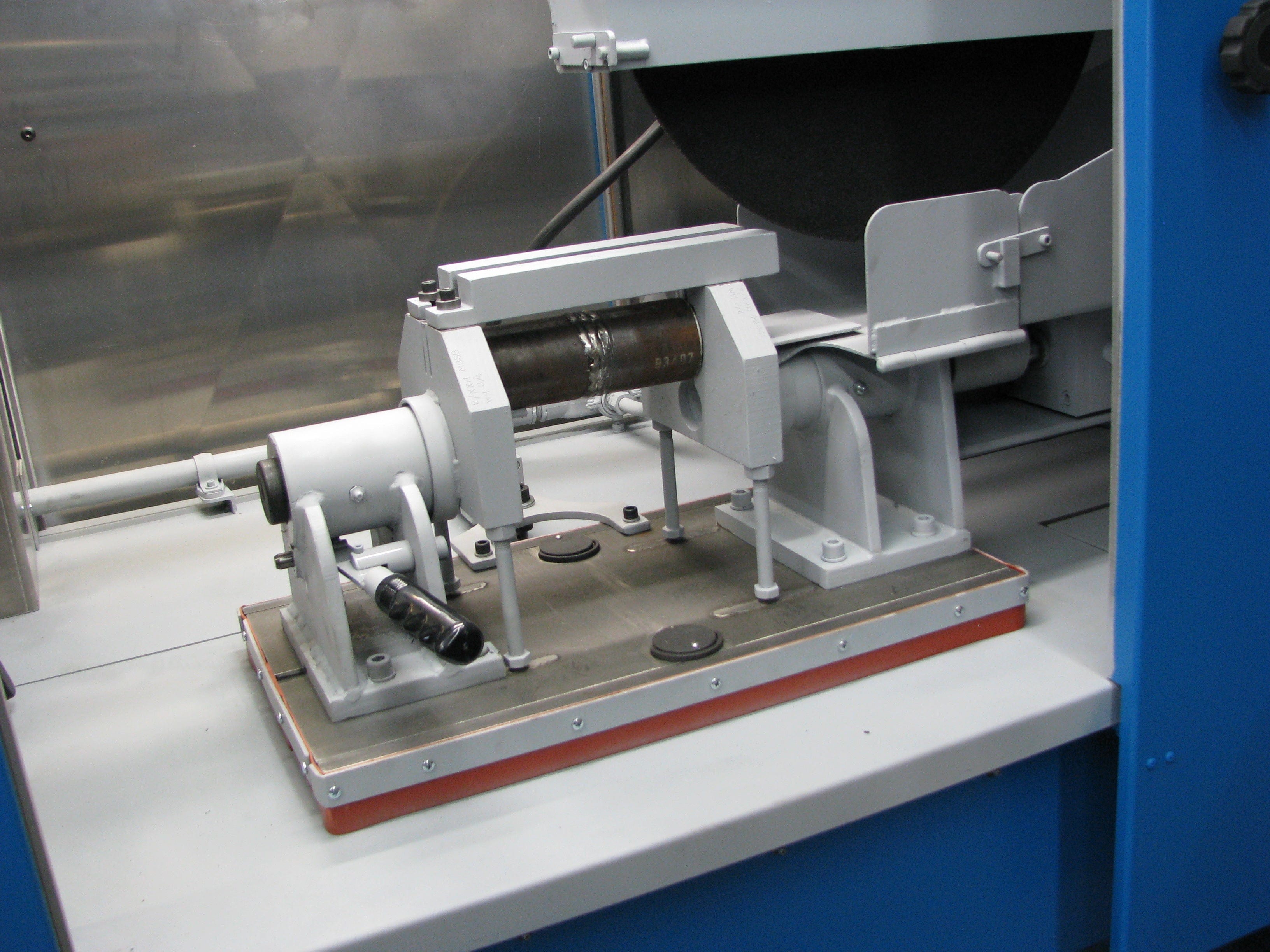

Backstrap Removal & Prep Tool, BSRT-15/10

Sale price$9,300.00

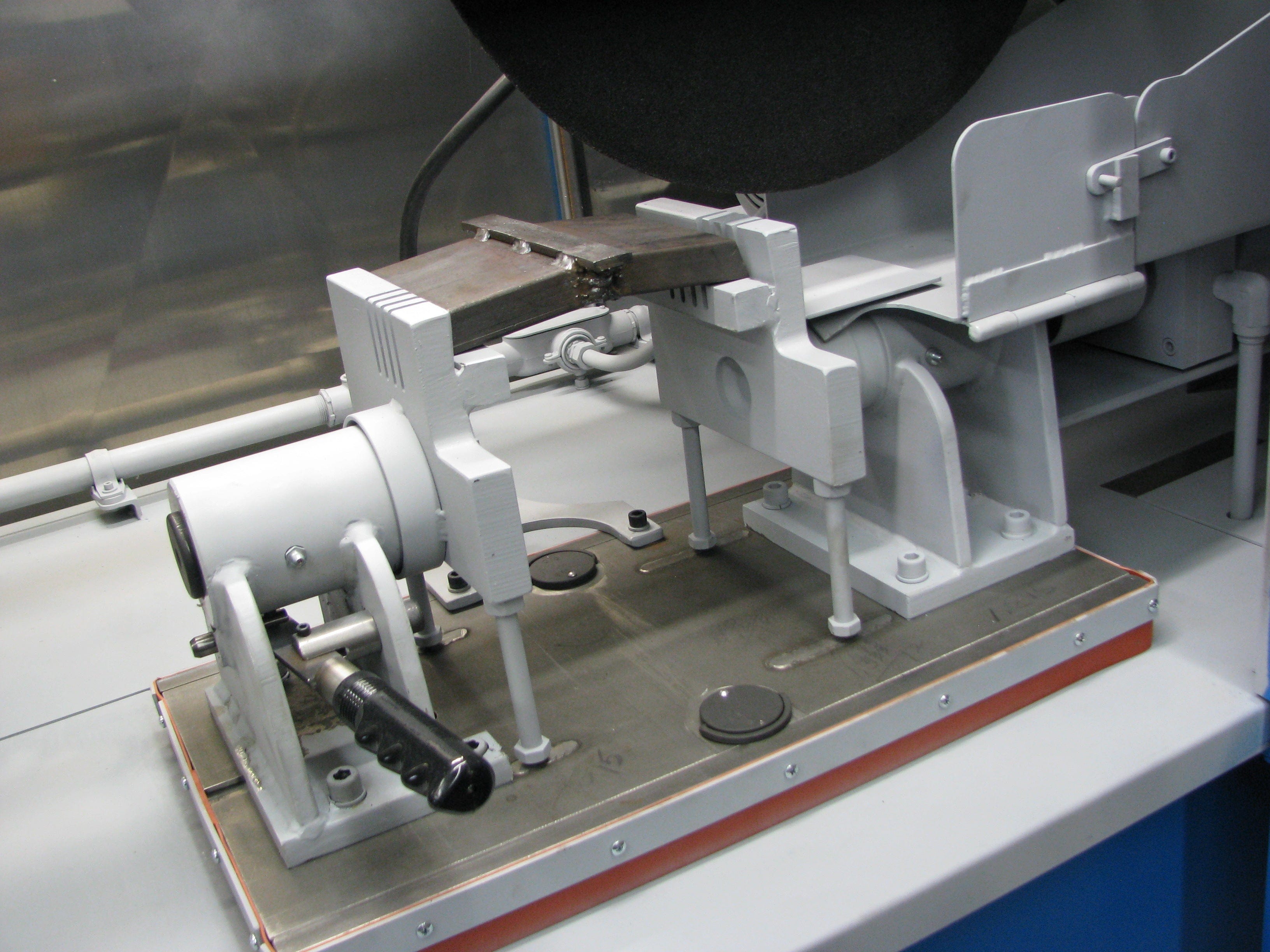

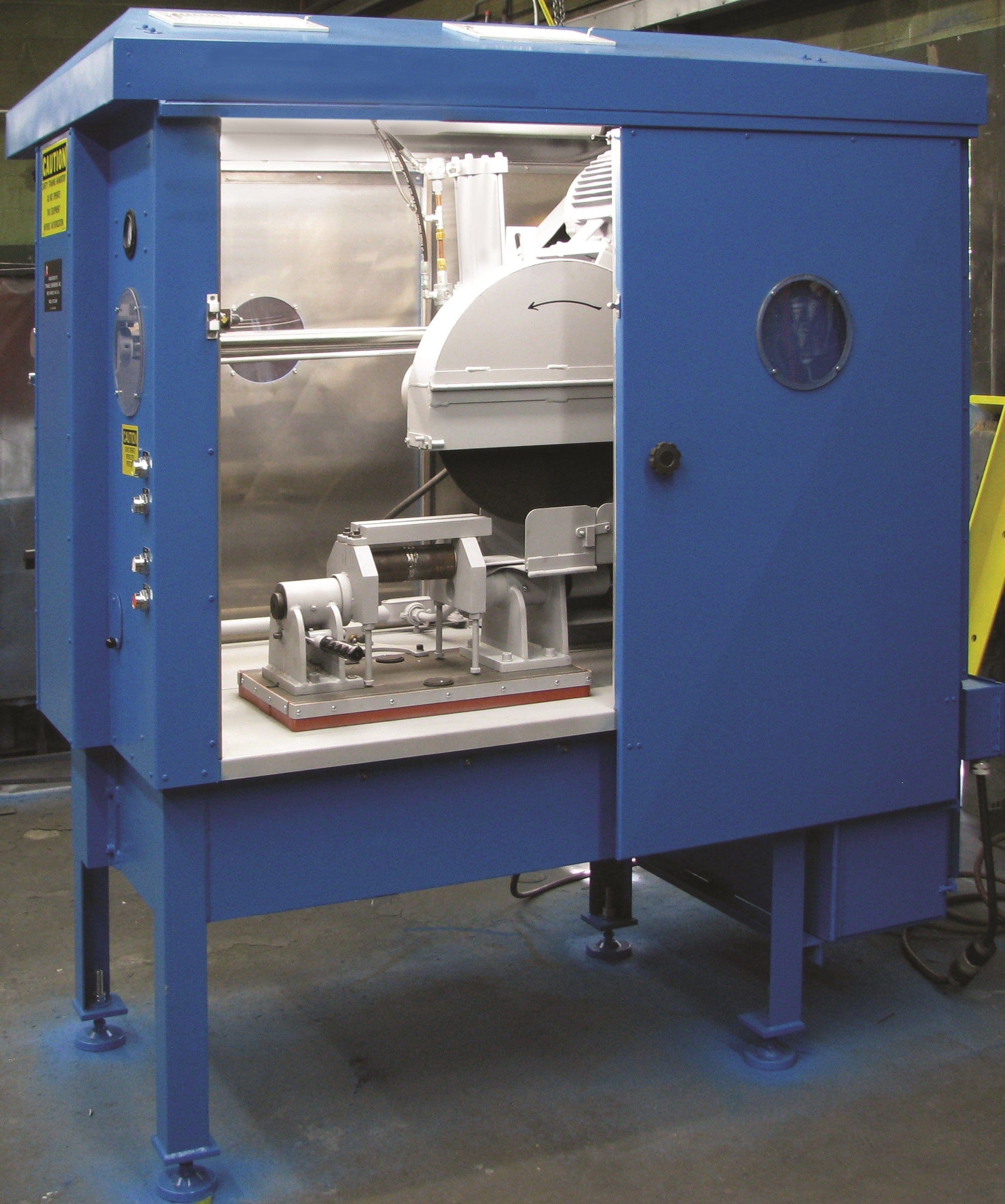

Weld Coupon Abrasive Cutter, WTC-20HR

Sale price$64,750.00

Filters (0)